UNDERSTANDING THE TECHNICALITY OF A TILE

UNDERSTANDING THE TECHNICALITY OF A TILE

An assortment of porcelain tile that are readily available in the market are bound to the following characteristics and behavior. Which once comprehend, would assist us in choosing the right product over the long run.

Alike any materials that are consumed, used or enjoyed, undeniably, are bound to have tolerances or so called “imperfection”. Thus, to pursue for precision materials by minimizing the tolerances is to allow the onset of international standards.

ISO Standards to state its minimum requirement in order to certify materials as good or poor quality products. By identifying and differentiating products that are of technically inferior or superior. Selecting high quality standard of porcelain tiles can be achieved despite any of its shortcomings.

THE DIMENSION QUALITY

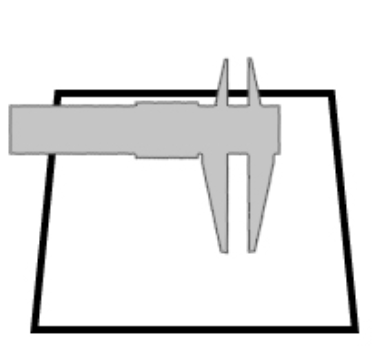

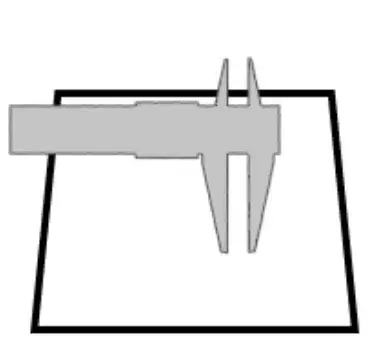

The regularity of the tile design will be attained if control over the importance of uniformity of dimensions within the same lot of tiles is evident. Measurement is in precision of 0.1mm.

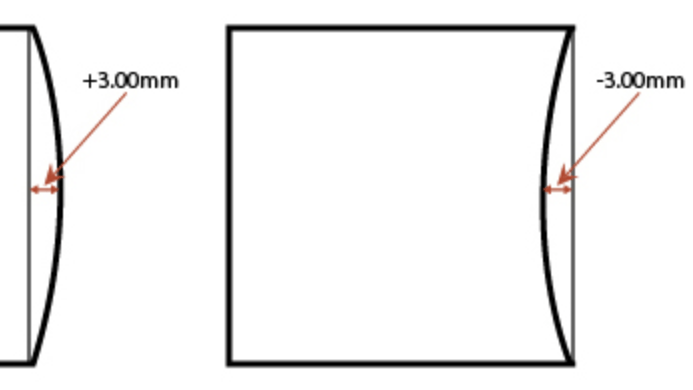

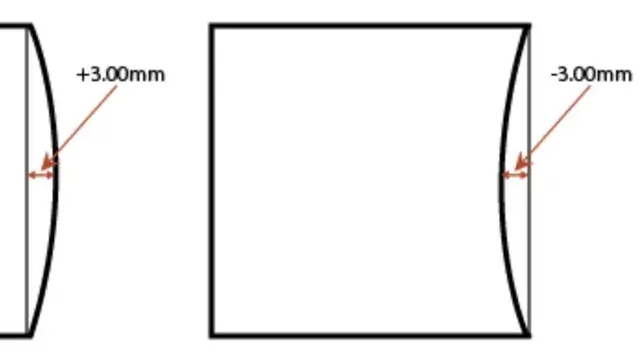

This parameter is controlled and measured by determining the deviation of the tile centre from the straight line that supposedly joins the tile corners in the plane of the tile.

EXAMPLE:

If a tile is declared with work size of a 600X600 mm tile as 600X600 mm, ISO standard says the maximum deviation from straightness corresponding to the work size must be kept within ± 0.5% which is 600mm X 0.5% = ± 3.00 mm.

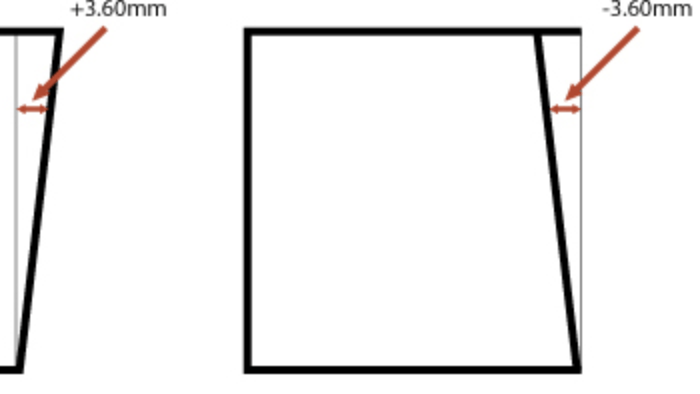

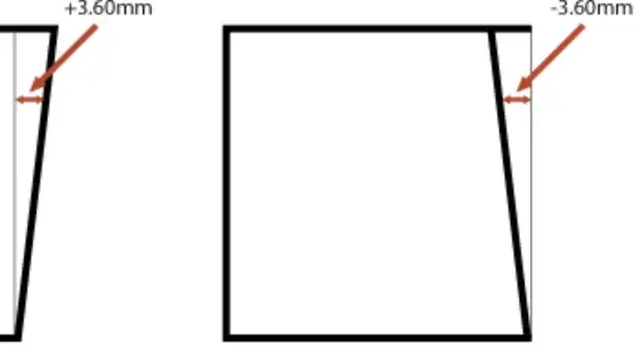

This parameter is to determine how closely the adjacent edges of a square or rectangular tile to form a right angle i.e. the tile is squared. This quality control would help to assure the regularity of tiles jointing of a minimum 2mm space, which should be as straight as possible.

EXAMPLE:

If a tile is declared with work size of a 600X600 mm tile as 600X600 mm, ISO standard says the maximum deviation from rectangularity corresponding to the work size must be kept within ± 0.6% which is 600mm X 0.6% = ± 3.60mm.

An assortment of porcelain tile that are readily available in the market are bound to the following characteristics and behavior. Which once comprehend, would assist us in choosing the right product over the long run.

Alike any materials that are consumed, used or enjoyed, undeniably, are bound to have tolerances or so called “imperfection”. Thus, to pursue for precision materials by minimizing the tolerances is to allow the onset of international standards. ISO Standards to state its minimum requirement in order to certify materials as good or poor quality products. By identifying and differentiating products that are of technically inferior or superior. Selecting high quality standard of porcelain tiles can be achieved despite any of its shortcomings.

THE DIMENSION QUALITY

The regularity of the tile design will be attained if control over the importance of uniformity of dimensions within the same lot of tiles is evident. Measurement is in precision of 0.1mm.

This parameter is controlled and measured by determining the deviation of the tile centre from the straight line that supposedly joins the tile corners in the plane of the tile.

EXAMPLE:

If a tile is declared with work size of a 600X600 mm tile as 600X600 mm, ISO standard says the maximum deviation from straightness corresponding to the work size must be kept within ± 0.5% which is 600mm X 0.5% = ± 3.00 mm.

This parameter is to determine how closely the adjacent edges of a square or rectangular tile to form a right angle i.e. the tile is squared. This quality control would help to assure the regularity of tiles jointing of a minimum 2mm space, which should be as straight as possible.

EXAMPLE:

If a tile is declared with work size of a 600X600 mm tile as 600X600 mm, ISO standard says the maximum deviation from rectangularity corresponding to the work size must be kept within ± 0.6% which is 600mm X 0.6% = ± 3.60mm.

SURFACE QUALITY

TILE SURFACE FLATNESS: Simply, a tiled area with surface flatness without “lippage”, waviness etc would be possibly obtained if emphases on the importance of this characteristic are apparent. This characteristic is determined by measuring the following:

List of Services

-

CENTER CURVATUREItem Link List Item 1

Deviation of the center of a tile from the plane in which 3 of the 4 corners lies.

EXAMPLE:

If a tile is declared with work size for a 600X600mm tile as 600X600m, the diagonal sector is calculated as 848.53mm. ISO standard for BIb and (water absorption rate 0.5%<E<3%) states that the maximum centre curvature related to the diagonal must be kept within ± 0.5% which is 848.53 mm X 0.5% = ± 4.24mm.

-

EDGE CURVATUREItem Link List Item 2

Deviation of the center of one edge of a tile from the plane in which 3 of the 4 corners lie.

EXAMPLE:

If a tile is declared with work size for a 600X600mm tile as 600x600mm. ISO standard for BIb and (water absorption rate 0.5%<E<3%) states that the maximum edge curvature related to the work size must be kept within ± 0.5% which is 600mm X 0.5% = ± 3mm.

-

WARPAGEItem Link List Item 3

Deviation of the fourth corner of a tile from the plane in which the other 3 corners lie.

EXAMPLE:

If a tile is declared with work size for a 600X600mm tile as 600x600mm, the diagonal sector is calculated as 848.53mm. ISO standard for BIb and (water absorption rate 0.5%<E<3%) states that the maximum centre curvature related to the diagonal must be kept within ± 0.5% which is 848.53 mm X 0.5% = ± 4.24mm.

Generally, it is a good industry practice if vigilance can be practiced prior to tiles installation by nipping in the bud or arresting any visual defects as and when the installers are to perform their work. Proceed immediately to inform the relevant suppliers for inspection of tiles that are in question.

Professional approaches to address the issue at hand will be samples being randomly collected from place of dispute and to be taken back to the principal’s test lab for testing and inspection to determine its quality and tolerances. Thereafter, the suppliers shall advice whether the tile in question is in compliance to the ISO standard or not while further discussion should commence to find an ideal solution.

SURFACE QUALITY

TILE SURFACE FLATNESS: Simply, a tiled area with surface flatness without “lippage”, waviness etc would be possibly obtained if emphases on the importance of this characteristic are apparent. This characteristic is determined by measuring the following:

List of Services

-

CENTER CURVATUREItem Link List Item 1

Deviation of the center of a tile from the plane in which 3 of the 4 corners lies.

EXAMPLE:

If a tile is declared with work size for a 600X600mm tile as 600X600m, the diagonal sector is calculated as 848.53mm. ISO standard for BIb and (water absorption rate 0.5%<E<3%) states that the maximum centre curvature related to the diagonal must be kept within ± 0.5% which is 848.53 mm X 0.5% = ± 4.24mm.

-

EDGE CURVATUREItem Link List Item 2

Deviation of the center of one edge of a tile from the plane in which 3 of the 4 corners lie.

EXAMPLE:

If a tile is declared with work size for a 600X600mm tile as 600x600mm. ISO standard for BIb and (water absorption rate 0.5%<E<3%) states that the maximum edge curvature related to the work size must be kept within ± 0.5% which is 600mm X 0.5% = ± 3mm.

-

WARPAGEItem Link List Item 3

Deviation of the fourth corner of a tile from the plane in which the other 3 corners lie.

EXAMPLE:

If a tile is declared with work size for a 600X600mm tile as 600x600mm, the diagonal sector is calculated as 848.53mm. ISO standard for BIb and (water absorption rate 0.5%<E<3%) states that the maximum centre curvature related to the diagonal must be kept within ± 0.5% which is 848.53 mm X 0.5% = ± 4.24mm.

Generally, it is a good industry practice if vigilance can be practiced prior to tiles installation by nipping in the bud or arresting any visual defects as and when the installers are to perform their work. Proceed immediately to inform the relevant suppliers for inspection of tiles that are in question. Professional approaches to address the issue at hand will be samples being randomly collected from place of dispute and to be taken back to the principal’s test lab for testing and inspection to determine its quality and tolerances. Thereafter, the suppliers shall advice whether the tile in question is in compliance to the ISO standard or not while further discussion should commence to find an ideal solution.

PHYSICAL PROPERTIES

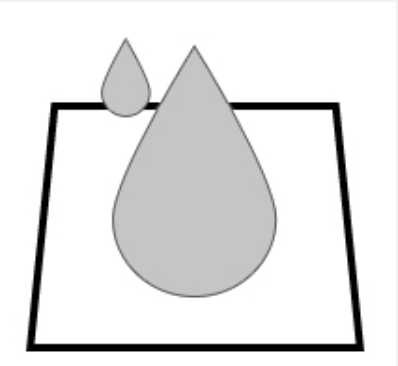

Is the quantity of water which a ceramic tile can absorb under controlled experimental conditions, expressed as percentage in weight of the dry tile. This main and important characteristic indicates the level of structure of the material. High water absorption rate signifies a porous structure, while the opposite implies a compact and vitrified structure.

In other words, the physical and chemical characteristics of a tile are depended on its porosity or water absorption which is a key parameter (as set out in ISO Standards) in determining tile functionality towards duress working environment i.e. the lower the water absorption, the better its resistance towards severe mechanical and thermo-hygrometric stress.

(Measured in N/mm²) is a material property, an indication of the maximum tension per unit area that a sample of the material, subjected to an increasing stress from being bent under specific conditions and with specific procedures, can withstand before breaking.

The resistance to bending is a property of the material that makes up the tile, and does not directly define any mechanical performance of the tile. It is measured to check the correctness of the production process used, to achieve the desired consistency and compactness.

Is the weight that, when applied under specific conditions and with a specific process, makes the tested tile break. The breaking strength is a performance property of a tile, and is determined by both the structural properties of the material and the thickness of the tile i.e. it tends to increase in tandem with the increase of the material’s both modulus of rupture and the tile thickness. In other words, the breaking strength of a single tile is usually much lower than the real weight-bearing capacity of the same tile in use when installed onto a floor. Mathematical models and calculations show that the weight bearing capacity of an installed tile is often greater by a factor of 20% to 80% to the weight that causes the break of a freestanding single tile during a test resistance on bending conducted in a laboratory. In conclusion, to achieve high performance resisting mechanical stress from a tile, that tile must receive complete bondage from other layers (screeding, bedding or structure) without any hollowness lying underneath but firmly bound to it.

or resilience, is its resistance to breaking from heavy blows caused by falling foreign objects. Like most ceramic materials that are fired under immense temperature and is brittle in nature, are not resilient, as any mechanical impact of a falling object may initiate the process of fracturing. Thus in general, the use of ceramic tiles requires a degree of care in avoiding the fall of heavy blunt objects.

In general, unglazed porcelain tile would have a better impact resistance than its cousin glazed ceramic tile due to the fact that a layer of thin glaze is a fragile material itself.

However, after all being said, fragility or brittleness of a ceramic must not be seen as defect, but as a property that, like all other mechanical, chemical and physical properties, is determined by the nature, chemical bonds and microstructure that are characteristic of ceramics while the resilience is also reliance on sound bondage with its substrate or bedding in totality.

Is the resistance of a surface to wear and tear connected with the movement of bodies, surfaces or materials that come in contact with it. There are a variety of bodies that move intentionally or accidentally over a floor tile such as the soles of shoes worn by people walking on the floor, the wheels of carts or other vehicles, furniture, chairs, and other loads which are dragged across the surface. A variety of materials like water, mud, snow, sand and organic substances etc may go in-between these bodies and the tiled surface. The daily operations of cleaning and maintenance with brooms, rags, detergents in powder, and so on also cause movement of hard materials over the tiled surface.

As such, these abrasive actions create two types effects:

I: the removal of material from the surface, which is gradually worn down;

II: the alteration of the aesthetic appearance of the surface, with loss of brilliance and variations in shade.

Both the above two effects may or may not occur simultaneously but it is important to note that especially for glazed tile, an intense and prolong abrasive action across a period of time will result in a partial loss of the glaze layer protecting the top, thus exposing its inner body. Thereafter, aside from immediate aesthetic effects, this removal of material generally will weaken the surface structure or its functionality, causing the tile in question becoming susceptible to porosity and micro-cracks (which is invisible to our naked eyes except under a microscopic view), finally leading to vulnerability to dirt, residues or stain penetration.

PHYSICAL PROPERTIES

Is the quantity of water which a ceramic tile can absorb under controlled experimental conditions, expressed as percentage in weight of the dry tile. This main and important characteristic indicates the level of structure of the material. High water absorption rate signifies a porous structure, while the opposite implies a compact and vitrified structure.

In other words, the physical and chemical characteristics of a tile are depended on its porosity or water absorption which is a key parameter (as set out in ISO Standards) in determining tile functionality towards duress working environment i.e. the lower the water absorption, the better its resistance towards severe mechanical and thermo-hygrometric stress.

(Measured in N/mm²) is a material property, an indication of the maximum tension per unit area that a sample of the material, subjected to an increasing stress from being bent under specific conditions and with specific procedures, can withstand before breaking.

The resistance to bending is a property of the material that makes up the tile, and does not directly define any mechanical performance of the tile. It is measured to check the correctness of the production process used, to achieve the desired consistency and compactness.

Is the weight that, when applied under specific conditions and with a specific process, makes the tested tile break. The breaking strength is a performance property of a tile, and is determined by both the structural properties of the material and the thickness of the tile i.e. it tends to increase in tandem with the increase of the material’s both modulus of rupture and the tile thickness. In other words, the breaking strength of a single tile is usually much lower than the real weight-bearing capacity of the same tile in use when installed onto a floor. Mathematical models and calculations show that the weight bearing capacity of an installed tile is often greater by a factor of 20% to 80% to the weight that causes the break of a freestanding single tile during a test resistance on bending conducted in a laboratory. In conclusion, to achieve high performance resisting mechanical stress from a tile, that tile must receive complete bondage from other layers (screeding, bedding or structure) without any hollowness lying underneath but firmly bound to it.

or resilience, is its resistance to breaking from heavy blows caused by falling foreign objects. Like most ceramic materials that are fired under immense temperature and is brittle in nature, are not resilient, as any mechanical impact of a falling object may initiate the process of fracturing. Thus in general, the use of ceramic tiles requires a degree of care in avoiding the fall of heavy blunt objects.

In general, unglazed porcelain tile would have a better impact resistance than its cousin glazed ceramic tile due to the fact that a layer of thin glaze is a fragile material itself.

However, after all being said, fragility or brittleness of a ceramic must not be seen as defect, but as a property that, like all other mechanical, chemical and physical properties, is determined by the nature, chemical bonds and microstructure that are characteristic of ceramics while the resilience is also reliance on sound bondage with its substrate or bedding in totality.

Is the resistance of a surface to wear and tear connected with the movement of bodies, surfaces or materials that come in contact with it. There are a variety of bodies that move intentionally or accidentally over a floor tile such as the soles of shoes worn by people walking on the floor, the wheels of carts or other vehicles, furniture, chairs, and other loads which are dragged across the surface. A variety of materials like water, mud, snow, sand and organic substances etc may go in-between these bodies and the tiled surface. The daily operations of cleaning and maintenance with brooms, rags, detergents in powder, and so on also cause movement of hard materials over the tiled surface.

As such, these abrasive actions create two types effects:

I: the removal of material from the surface, which is gradually worn down;

II: the alteration of the aesthetic appearance of the surface, with loss of brilliance and variations in shade.

Both the above two effects may or may not occur simultaneously but it is important to note that especially for glazed tile, an intense and prolong abrasive action across a period of time will result in a partial loss of the glaze layer protecting the top, thus exposing its inner body. Thereafter, aside from immediate aesthetic effects, this removal of material generally will weaken the surface structure or its functionality, causing the tile in question becoming susceptible to porosity and micro-cracks (which is invisible to our naked eyes except under a microscopic view), finally leading to vulnerability to dirt, residues or stain penetration.

THE TEST METHOD FOR GLAZED TILES UNDER ABRASION RESISTANCE IS THE PORCELAIN ENAMEL INSTITUTE (PEI) RATING.

The method consists of a visual assessment, according to specific conditions of observation, of the effect produced by abrasion of the tile surface with specified amounts of abrasive material using an apparatus designed for carrying out this test with increasing intensity. The resulting observations are assigned to a class of abrasion resistance, with increasing order of resistance, according to the following classifications:

Classes

CLASS I : Tile for areas that are walked on essentially with soft soled footwear or bare feet without scratching dirt (e.g. bathrooms and bedrooms in private homes without direct access to the outside).

CLASS II : Tile for areas that are walked on with soft soled or normal footwear with, at the most, occasional small amounts of abrasive dirt,(e.g. rooms in the living areas of homes, with the exception of kitchens, entrance ways and other rooms which may have considerable traffic).

CLASS III : Tile for areas that are walked on quite often with normal footwear and amounts of abrasive dirt,(e.g. halls, kitchens, corridors, balconies and terraces).

CLASS IV : Tile for areas that are subjected to considerable traffic with some abrasive dirt so that the conditions are the most severe for which glazed floor tiles are suitable,(e.g. entrance, work rooms, restaurants and exhibition and sales rooms as well as other rooms in public and private buildings not mentioned in Classes I,II and III).

CLASS V : Tile ideally suitable for heavy traffic areas under normal foot traffic conditions such as in all residential and heavy commercial areas.

In many cases, even though glazed tiles are being classified as above, the specific requisite will depend on what has been agreed, case by case, between producer-seller-buyer-consumer. For this reason, the resistance to abrasion, with such classifications, produces convenience, precise and fundamental criterion for choice of the tile as a function of its intended working environment.

Note that the PEI V class of resistance is assigned to tiles that not only show no visual evidence of abrasion, but also continue to manifest adequate stain resistance and clean ability.

THE TEST METHOD FOR ABRASION RESISTANCE OF UNGLAZED TILE IS THE DEEP ABRASION TEST.

The method entails measuring the volume of material removed from the surface of the tile by means of rotating disc under specified conditions and the use of abrasive material. The results from this test are more related to the technical performance of the tile surface rather than to the aesthetic effects.

Moreover, for unglazed tile, the damage caused by abrasion is lesser because any removal of the tile surface caused by abrasive action only reveals an underlying layer of the same composition and therefore with the same appearance as the original surface without altering its functionality.

THERMAL SHOCK refers to sudden and unexpected variations of temperature of floor or wall tiles due to accidental or intentional contact with hot or cold substances (such as from the fall of a boiling liquid, hot vapors used for cleaning, or, in the case of exterior floors or walls, from sudden temperature shifts). Thermal shock resistance is the characteristic which indicates whether or not the tile is capable of withstanding such rapid changes in temperature without being damaged.

THE MOISTURE EXPANSION corresponds to the expansion, expressed in mm/m, which a tile may undergo as a result of the adsorption of moisture. The tendency for this behavior is more or less exclusively for porous tile. Thus testing for this characteristics is required only for unglazed tile with values of water absorption greater than 6% (specifically, tile falling into Groups Allb, Alll, and Bllb).

FROST RESISTANCE

Is the characteristic which some types of ceramic tile have to resist the action of frost in humid environments and at temperatures below 0°C which commonly occurs in temperate countries.

The mechanism of frost action involves two distinct steps. The first step is the penetration of water into the pores of the tile, and the second is the solidification (freezing) of the water inside the pores.

As is well known, the transformation of water from the liquid to the solid state is accompanied by an increase in volume due to the fact that density of ice is less than that of water. For this reason, when the water inside a pore freezes, it subjects the material to considerable mechanical stress which can lead to cracking of the tile and possibly breaking-off of a portion of the material. The action of freezing, therefore, can give rise to the appearance of fractures and chipping.

Based on the mechanism described, the frost resistance of a material is determined by two parameters:

- the presence and quantity of pores, thus the possibility that water will penetrate into the interior of the material, and

- the shape size of the pores present, thus, depending on the more or less complete filing of the space available, the amount of space the water has in which to expand during freezing which, in turn, determines the degree of stress induced.

Consequently, there exists a certain correlation between frost resistance and water absorption: the lower the water absorption, the greater the probability that the material will be frost resistant. However, the choice of frost resistant tile is certainly indispensable for tiled surfaces exposed to high humidity and low temperatures, but that alone may not be sufficient to avoid the appearance of frost damage, because not only the tiles, but rather the whole floor or wall system must be frost resistant.

THE SLIPPERINESS OF A SURFACE

Is the characteristic which describes the kinetic and dynamic conditions of the movement of a body in contact with it. Floors, in this case here, is immediately evident how the slipperiness is closely related to the safety of walking across it. Today this characteristic is increasingly gaining attention, partly because of laws and regulations which establish the strict responsibility of the owner of the floor with respect to accidents and damages to third parties caused by falls.

One of the many reliable parameters used to characterize the slipperiness of a surface is the COEFFICIENT OF FRICTION. The higher the coefficient of friction, the less slippery is its surface. The coefficient of friction depends on the nature of the two bodies in contact as well as on the conditions of contact itself whether with or without the presence or absence of material interposed between the surfaces, the humidity and temperature conditions.

The coefficient of friction, in comparison with that for a dry, clean surface, decreases in the presence of oil, grease, dirt, water, and other materials which serve as lubricants between the sole of a shoe and the floor. When such materials are present, therefore, the slipperiness of the floor increases as does the risk of falls and accidents.

Rough surfaces tend to have higher coefficient of friction. Any uneven roughness can be naturally or expressly obtained by creating various types of relieves of shapes and sizes. This is because uneven surfaces inhibits the formation of an incessant film of liquid, responsible for the decrease in friction, even with the presence of water or other form of liquid.

Nevertheless, such surface profiles that provide ideal condition of safety with regards to prevent slipping and falling also cause the surfaces to be more difficult to clean. This is an important factor which must be kept in mind when choosing a floor covering, like if we in dire need to choose safety over cleanliness opt for darker tone of colors to offset its “shortcoming”. Ceramic tile, especially unglazed tile, in general is one of the least slippery materials among those most commonly used for floor coverings.

CHEMICAL PROPERTIES

CHEMICAL RESISTANCE refers to the behavior of the ceramic surface when exposed to aggressive chemicals which, due to their composition and properties, corrode the ceramic surface and penetrate it permanently or even alter its aesthetic appearance.

Highly acidic or alkaline base chemicals may be found in various processed liquids (like milk in a cheese factory, lubricating grease and oils in an automotive repair shop, blood in a slaughterhouse, and laboratory chemicals), and other materials that may come accidentally into contact with floor or wall tiles (like foods, ink, rust, oil and so forth in a private residence), as well as detergents for ordinary and extra-ordinary cleaning and maintenance.

Deterioration of a ceramic tile surface caused by the various chemicals cited above is generally compounded to two distinct mechanisms effects:

- an actual chemical reaction between the substance and tile resulting in alteration of the ceramic surface (ceramic surfaces, in general, are inert to any reaction of chemicals, with the sole exception of any fluoride compound and its derivatives); and

- the chemicals penetrate below the tile surface permanently and become extremely difficult to remove in some way or another. This is partly attributed to the fact that any form of severe abrasive nature or condition can cause the chemical resistance of a ceramic surface to deteriorate when certain level of micro-porosity starts developing.

The results of these test allows tiles to be classified to a particular class of resistance, for each staining agent or for each chemical specified in the standard. The classes, in decreasing order of resistance are as follow:

- STAIN: Class 1, Class 2 and Class 3; (Class 1: good resistance to staining; Class 3: persistence to stains, and thus poor resistance.)

- CHEMICALS: Class AA, Class A, Class B, Class C and Class D. (Class AA: optimum resistance to chemicals; Class D: poor resistance to chemicals.)

Address: 309 Glenwood Road, Faerie Glen, Pretoria 0081

Email Address: sales@sinotile.co.za

Phone: 012 - 010 3270

Working Hours

Monday - Friday: 8am-5pm

Saturday: 8am-12pm

Sunday: Closed

Sinotile | Privacy Policy